Formula 1 is ostensibly motorsport at its most changeable. Cars are redesigned constantly, chasing speed. Fresh ideas are everywhere. Still, that creativity has fences. Some ideas are off-limits.

Racing rulemakers issue tech bans for many reasons. Often to foster entertainment, or fairness, or creativity in engineering.

As your narrator typed those last few words, he laughed. A single burst: ha!

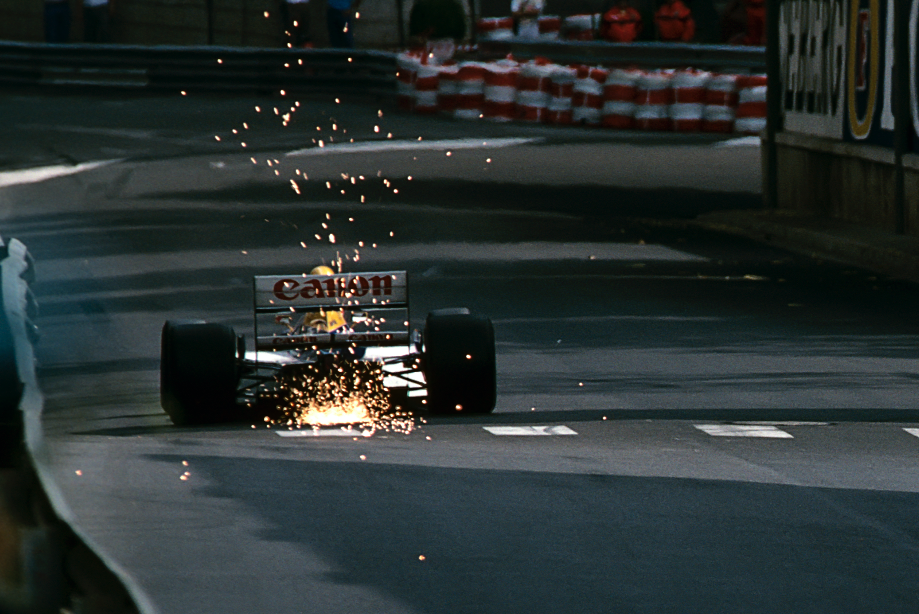

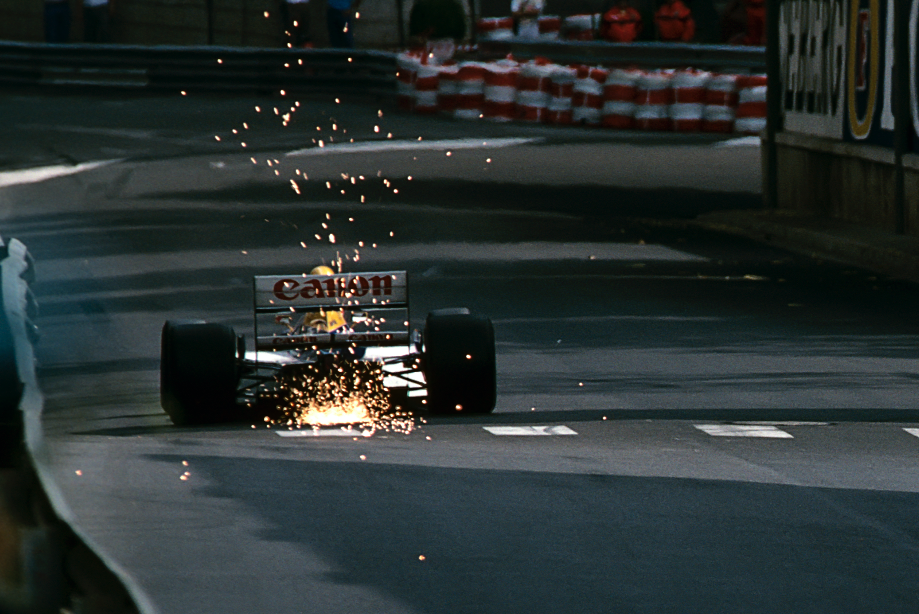

This is a 1992 Williams FW14B: English F1 car, Englishman in the cockpit. When this photo was taken, in Monaco, on the 31st of May in 1992, Nigel Mansell was 39 years old, in the prime of his career. His bushy moustache and thick eyebrows were famously proper. Let us now look at Nigel from a different angle:

For one whole year, that ‘stache and car ate Formula 1 whole. The peak of global motorsport, some of the world’s sharpest talents, smacked around by a middle-aged father of three with a lip rug like a video-game plumber.

Mansell was born in 1953. His first F1 start was in 1980, in a Lotus. Over the next decade, he would carry on driving for Lotus (1980–1984), move on to Williams (1985–1988), and finally arrive at Ferrari (1989–1990). That last stint must have been depressing. Ferrari in 1990 was, as the saying goes, very Ferrari. A legendary palace whose strengths are so often outshouted by the house tendency to step on its own – we will use the polite term here – Richard.

The Italians called him il leone, the lion. And yet they could not give him a worthy car. Mansell’s time with Maranello was such a raging ball of stink, he considered retiring from F1 altogether. Before pulling that trigger, however, he met with his old friends at Williams.

The English team shared with him its future plans. There were details of the machine Williams was set to run in 1991, the FW14. That car would eventually be updated and run in 1992 as well. In the latter guise, it would be called FW14B. And so he signed with Williams a second time, because he knew a cannon when he saw one.

If Mansell and the 14B were a hammer, the ’92 F1 field was a thumbtack. That year held 16 races. Mansell won the first five going away, just checked out. By season end, he had walloped his way through a total of nine wins, but also 14 pole positions and eight fastest race laps. He notched this achievement while competing against names like Senna, Schumacher, and Hakkinen.

How great is that image? Imagine the pubs that year. Dark rooms full of cranky old men raising large pints to small TVs, yelling toasts like Our Nige! and noting how England’s latest grid-stomper looks like real people, just a meat-and-potatoes guy. Those men would nod and remark on how, you know, exercise is fine and all, but you shouldn’t become a caricature, should you, just look at Mika Hakkinen – fast, sure, but who can get excited about a man who looks like a cross between Val Kilmer in the ’86 Top Gun and the feeling you get after eating too much cheese?

Stout moustache, they’d say. Trusty-lookin’ bloke. Like Graham Hill.

At the end of the season, our pushbroomed not-a-Mario was crowned world champion. No one was surprised. He had locked the title in August.

***

Take a moment to imagine life on an F1 team. Where every measurement of success is tied to going faster. Where a design can become hopelessly obsolete weeks or even days after it has first turned a wheel.

Imagine that your team has just finished a new car. That machine represents millions of dollars of R&D and thousands of hours of work, and everyone knows it is a step forward from your previous design. On top of that, every minute that car is not raced and improved, it grows slower, and the competition inches closer.

Now consider what it would take to make you park that car and run the old one instead.

Again, the 14B was a ’91 design. Williams modified the car for 1992 and used it to start that season. The 14B’s replacement, the FW15, was in the works, so they planned to swap to it in summer. Summer came and went. The 15 was finished, but it stayed at home for the rest of the year. The old rig was simply that much of a fireball.

Every Formula 1 car is designed by a small army of engineers. Those individuals have some creative freedom but work to the compass of a chief engineer. The 14B was chiefed by Englishman Adrian Newey. In 1992, at just 33 years old, Newey was in his prime. In 2024, at 65, Newey is the chief technical officer for Red Bull, still in his prime.

Newey came to Williams, in 1990, from a smaller team. He did this partly because Williams had better funding – enough money to develop certain ideas.

One of those ideas was active suspension, a technology now illegal in Formula 1. Active suspension is to regular suspension as Taylor Swift is to Taylor ham: They’re each built from the same basic components, but beyond that, things get complicated.

The greater point is how the 14B’s dominance prompted significant changes in the sport for which it was created, and how the wake of that dominance is visible even today. F1 has always struggled to balance innovation and stagnancy. The Williams, however, is widely seen as the last great and compelling technical leap. When the tech at the core of that leap was banned, the series turned a corner, for better or worse.

***

The 14B was first raced in March 1992, in South Africa. This was the first grand prix of the year. At that point, as this fun little book notes, the Williams was “the most technologically advanced car ever to compete in F1.”

What does that mean? Let’s examine the pieces:

It had a fast, exotic gearbox that didn’t blow up. The paddle-shifted transmission arrived in Formula 1 in 1989, in the Ferrari 640. That technology replaced the traditional manual gearbox and is now ubiquitous; when a computer handles shifting, lap times drop. The 640 gearbox was early days, however, and it often broke. Three years later, the tech had spread to other teams but was still in its infancy. Durability remained a dice roll, and some cars stuck with manuals.

The 14B’s gearbox was built in-house, an evolution of a Williams design for ’91. Team director Patrick Head later called the transmission’s early reliability “appalling.” They fixed it, however. By 1992, the Williams transaxle shifted faster than any other ‘box on the grid and was as dependable as a stone axe.

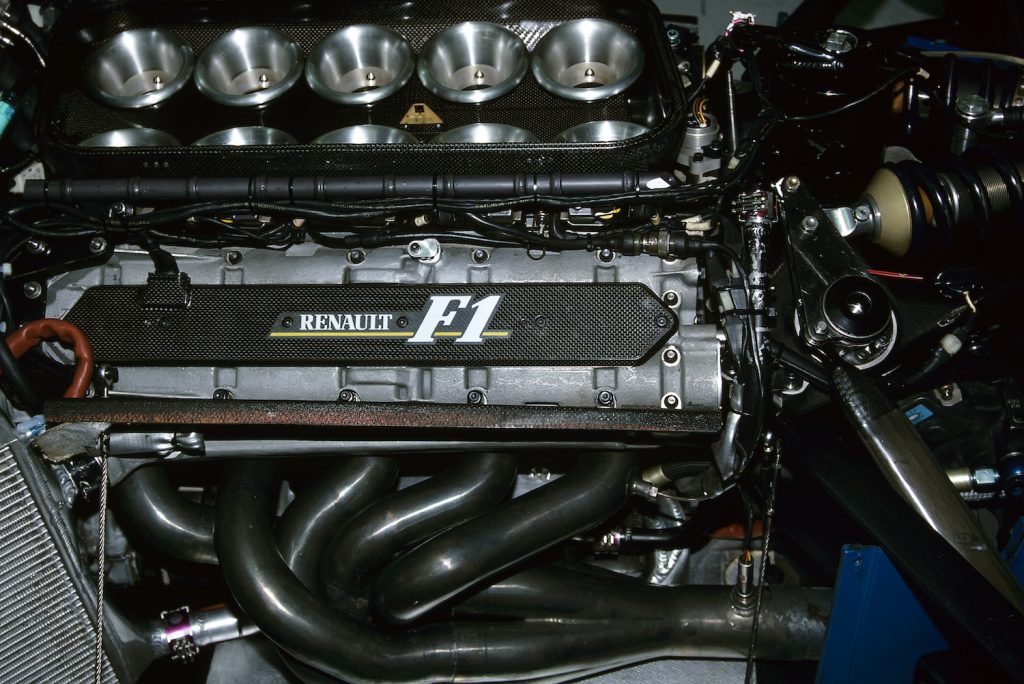

It had a Renault V-10, tiny and strong. Ten cylinders, 3.5 litres. That engine weighed 300 pounds and made more than 750bhp at more than 14,000rpm. Those figures were not outlandish for the period but stronger than average. More important, at a time when annual engine redesigns were common, the Renault was old. It had been drawn up for and run in 1991, then simply evolved to unburstable. (Notice a trend?)

There was a central chassis computer, the Williams Vehicle Control and Monitor module (VCM). And man, it is hard to type those words without falling asleep. Computer controls car – no big deal, even then, right?

No high-speed automobile had ever worked with silicon in such fashion. The VCM was designed in-house, ground-up, from software to hardware. It managed, among other things, the 14B’s suspension, engine, gearshifts, and traction control via CAN bus.

“CAN” is an acronym: Controller Area Network. It is a digital communications protocol developed by Bosch and released in the late 1980s. In a nutshell, the technology lets separate digital components rapidly talk to each other without a central “host” computer. In the Williams, CAN’s speed and efficiency opened a door. It let the car be tuned holistically, as something like one big digital piece.

Just as important: Williams engineers knew this trippy little digital moustache saddle would be a living organism, changing from weekend to weekend or even lap to lap. So they designed its code and setup files to be alterable, in the pits, with a PC.

On a race car governed more by software than any before it, at a time when most onboard computers were reprogrammed by cracking open a control module and physically swapping chips, the 14B could be tuned with a keystroke.

Remember that active suspension? We’ll come back to this part.

Most racing teams of the era did not treat computers like this. Outside F1, few automotive engineers even had the funding to try. CAN is now ubiquitous in road cars, but the ramp was slow. The tech first met showrooms in the 1991 Mercedes S-class, where it was slow and buggy.

If you have not yet gathered, next to a 14B, that Mercedes is as much a computing problem as a cheese sandwich.

This was all hugely complex. So they chased ways to simplify it. Data is everything in motorsport. It is hard numbers, inarguable result, critical barometer. Quantifiable evidence of how car and driver are working or falling down.

The Williams was a data beast. Because its complex active suspension was tuned almost entirely with software, yes. But also because that suspension changed in such subtle and rapid fashion that its actions weren’t always parseable by a driver in real time.

With the 14B, Williams ditched old conventions of data presentation. Priority shifted to efficient visuals and quick trackside conclusions. Thirty years later, that approach is datalogging SOP all the way down to club racing. The 14B’s data system also featured one of the earliest uses of a removable memory card – 250KB at first, 1MB by season’s end – for rapid downloads.

The 14B used electronic traction control. Designed and developed by Williams, managed by the VCM. Software compared wheel speed to engine speed, cutting ignition when necessary. This practise was then common in F1, but the “holistic” chassis approach helped it work.

There was a hydraulically operated throttle “blipper,” for downshifts. A mid-season introduction. Most early paddle gearboxes required the driver to manually blip the throttle on downshifts: a quick stab of rpm from the right foot, usually while braking.

The 14B had a traditional cable throttle. It also had a hydraulic throttle actuator – that blipper – used only on downshifts. With that actuator engaged, the driver’s foot and brain were free to focus solely on braking.

If this sounds over-the-top, huge effort for small gain, that’s because it was. (Welcome to Formula 1.) But the Williams already had a complex hydraulic system and formidable software controls, so the blipper was a relatively easy add.

Before we move on, it helps to remember the speeds at play. A 1990s F1 car is slow by modern standards, but the worst car on the ’92 grid was still a 200-mph device. Few decisions, whether human or silicon, took place after a glut of time to think.

When the 14B was new, most consumer PCs were heavy and large. Picture two briefcases stacked atop each other, too heavy to be lifted by a child. The Williams VCM was the size and shape of a cigar box and half as tall. It weighed just over two pounds.

There was a “blown” diffuser. Look at the shot above: Ayrton Senna’s 1991 crash in Mexico. The floor of his McLaren is flat, almost featureless. Then, between the rear wheels, something else. That’s a diffuser.

Race-car diffusers produce downforce. Their shape helps accelerate passing air, lowering air pressure under the car. That low-pressure zone “sucks” the car toward the ground, in a sense, aiding grip. If you feed, or blow, additional high-pressure gas into this diffuser – say, engine exhaust – the air will accelerate further. There is then more pressure decrease, and downforce rises.

Here’s where it gets complicated: The amount of added downforce – of grip – is directly related to the pressure and volume of the blown gas. Internal-combustion engines generally produce the most exhaust-gas pressure at big throttle and high rpm. All else being equal, a car with a blown diffuser will produce significantly more downforce when the driver is on the throttle.

The FW14B had a simple blown diffuser. It looked something like this:

Diffusers of this type had been in Formula 1 for years. When Ayrton Senna first tried one, he was so excited, he went on the radio and told his crew it was “better than sex.

Newey, for his part, simply used the tech well.

***

A Short Digression on the Blowing

Success in F1 is all but impossible without a good car, and the 14B was one hell of a good car. But Mansell was also Our Nige, leone con dadbod, moustache-excelsior. In 1992, he was teamed with Riccardo Patrese, an Italian. Patrese was talented, but in a virtually identical car, he simply struggled more than Mansell and went noticeably slower.

Consider that diffuser. Minimising lap time with such a device can mean adding throttle in ballsy situations. Earlier in a corner, for example, where an “unblown” car might simply see the extra boot of entry speed and huck you into the pea gravel.

In 2014, former Williams tech chief Paddy Lowe summed things up for Autosport: “It required a lot of confidence from the driver. The combination of Nigel’s balls and that ’92 car was unbeatable, because he trusted the downforce would be there when he hit the throttle.”

Related trivia: Two decades later, the blown diffuser returned to F1. It was reintroduced by another Newey design, the 2010 Red Bull RB6. Which also stomped its way to a championship. Newey, an understated man, later said the RB6 made what was likely “the most downforce in the history of F1.” The Red Bull diffuser used exhaust gas, as on the Williams, but in more complex fashion, and with more digital management. By carefully tweaking engine variables like spark advance, off-throttle fuelling, and valve timing, the RB6’s V8 was manipulated into producing significant exhaust pressure regardless of throttle position.

Naturally, Formula 1 banned that, too.

***

And Now, without Further Ado: The Party Trick

Race cars are systems. The 14B’s active suspension was just one piece of the puzzle. But it was a staggeringly good piece.

Active suspension solved a problem that had dogged F1 engineers for years. Williams did not invent the technology, but they did implement it better than anyone else. And in a way that helped Mansell constantly romp to the front. That often let him finish 20 or 30 seconds ahead of the next car. No points for guessing the end result. (Say it like those Latin football announcers: Bannnnn!)

Back to that first Monaco shot. Look inside each front wheel, near the Labatt’s logo. See the diagonal suspension arms? Those are suspension pushrods. Each outside end is mounted to a wheel upright, the large cast component that carries wheel bearings, brake components, and so on. In a “traditional” modern race car, those pushrods translate the vertical motion of each wheel to dampers and springs mounted in the body. Notice how the pushrods go into those little lumps in the bodywork?

This is the F1 field at South Africa in 1992. The blue and yellow machines are 14Bs. Mansell is in car 5, leading. Now look at the rest of the pack.

Same pushrods, no lumps.

Under that nose lives this relatively simple swarm:

Before we can discuss why active suspension made such a difference, we must discuss aerodynamic downforce in motorsport. The production of grip – traction – on a racing vehicle, through aerodynamic components.

Picture an upside-down aeroplane wing. The lift generated by that wing will want to “fly” it toward the ground. Mount that upside-down wing on a car, that force will allow the car to corner faster. (Not all downforce components are wings – you can achieve the same end with diffusers, body tunnels, fans, ground-effect, the list goes on – but the principle is the same.)

Downforce cars have a unique problem: When you ask air to do work, it can be extremely effective.

In the late 1970s, when automotive downforce was young, race engineers discovered something remarkable: With the right wing and body shaping, an F1 car could generate thousands of pounds of download without suffering significant penalties in drag or weight.

Thousands of pounds of invisible force, pressing the tyres into the track, aiding grip. In a car that might weigh 1200 pounds.

On one hand, this is great. More grip usually makes a car go faster. On the other hand, every racing car has a suspension and a driver, and each must do a job.

The suspension has to keep the car’s body off the pavement. It also has to keep the tyres evenly loaded, for maximum grip and controllability and minimal wear. The suspension must keep any aerodynamic components at their designed heights and angles, so they meet oncoming air properly and do their best work.

The driver must be able to control the car at the limit of adhesion. While managing tyre degradation and race traffic, while developing and executing complex tactics, while undergoing significant physical abuse, while consistently driving as fast as possible.

That is a remarkably complex – and interwoven – stack of problems.

In a modern F1 car, none of those problems exists in a vacuum. Solve one without considering the rest, the car will likely be slower. Aero is usually the most important item on the list, simply because it can impact lap time the most.

In racing, much of aerodynamics management comes down to the management of ride height. The distance between the car and the ground. Keep that distance constant front to rear and left to right, your wings stay working their best, stay happy.

Most cars are held off the ground by springs. The stiffness of that spring is a major factor in a suspension’s state of tune. Picture a coil spring, which compresses and shortens with load. An F1 car without aerodynamic downforce might need coils of a certain stiffness, or rate, to give the lowest lap time at a given track. Let’s call that stiffness 1X.

Add downforce, things change. Air piles load into the car’s body, that load is transferred to the springs, the springs compress. (F1 rules stipulate that major aerodynamic elements be mounted to, and send load through, the bodywork. The situation is a bit different if your wings are mounted elsewhere – directly to the suspension, for example – but that’s another discussion.)

Take our hypothetical 1X springs. Under that new aero load, they collapse and go solid—they reach coil bind. Countering the added load might require a spring with a rate of 1.5X, maybe even 2X. Perhaps the springs are not collapsing, and you simply want to keep ride height more consistent under roll and pitch and heave. Either way, you are going stiffer.

(Fun fact: Some race cars are designed to collapse their springs in certain situations; NASCAR Cup cars are known for it. Outside certain cases, however, the path is rarely ideal.)

Fine, you think: Just run really stiff springs, right? Order up some fatties to match your downforce, leave it at that? Sure! Except: Stiffer isn’t always better.

All else being equal, stiff springs can make a racing car sketchy and fatiguing at the limit. Early aero cars of high spring rate often tied that condition to hugely inconsistent tyre wear. Beyond that, there’s the problem of bumpy tracks, where a certain amount of relative suspension compliance – softness – is necessary to keep a tyre on the ground and evenly loaded. The list goes on.

***

And so the answer came from questions

Early on, the answer was simply grin and bear it – the downforce was worth those penalties. Then a few people began to ask entirely reasonable questions.

What if you could make a car stiff when you needed but soft when you didn’t? and Can aerodynamic tuning be divorced from chassis tuning?

Because Formula 1 in those days was relatively low on rules, a host of answers resulted. Lotus, for example, famously pursued a “twin-chassis” layout, using one suspension for aero bits and another for everything else. Various mechanical addendums were considered and developed. (If you really want a rabbit hole, google “heave damper” and “inerter,” then consider how those two items are basically caveman solutions. Modern F1 teams do some spooky-cool work in the field of height control.)

The fun one, though, was active suspension.

In many ways, this was the ideal solve: A suspension where setup could be altered on the fly, soft one second and stiff the next. From track to track, of course, but also lap to lap or even corner to corner. To suit changing conditions, perhaps. Or even just the differences between, for example, Turn 1 and Turn 3.

Stiffen the front to reduce brake dive into slow corners, keeping the wings level, then soften it an instant later for more grip on turn-in? Done!

Maintain ride height within a millimetre at 180mph, but also keep the car controllable and grippy at half that speed, and always easy on tyres? Done!

Flick a cockpit switch when it begins to rain mid-race, softening the car so it works better in the wet? Done!

All you’d need is a fast and only lightly revolutionary computing approach to control it. Like, say, that VCM.

Above: The 1993 Williams FW15C cycling its active suspension at Monza. The system’s layout and operation differed slightly from that of the 14B—note the rocker arms at the top of the pushrods, and the relocated actuators—but the principle and result were the same.

Lotus and Williams were just two of the teams that went down the active rabbit hole. Each played with hydraulics. Each team abandoned the technology, then came back to it, then abandoned it again.

With the FW14B, Williams finally stuck the landing. Just as important, they were smart enough to pair the system with known quantities—a reliable engine, a proven gearbox, a special driver.

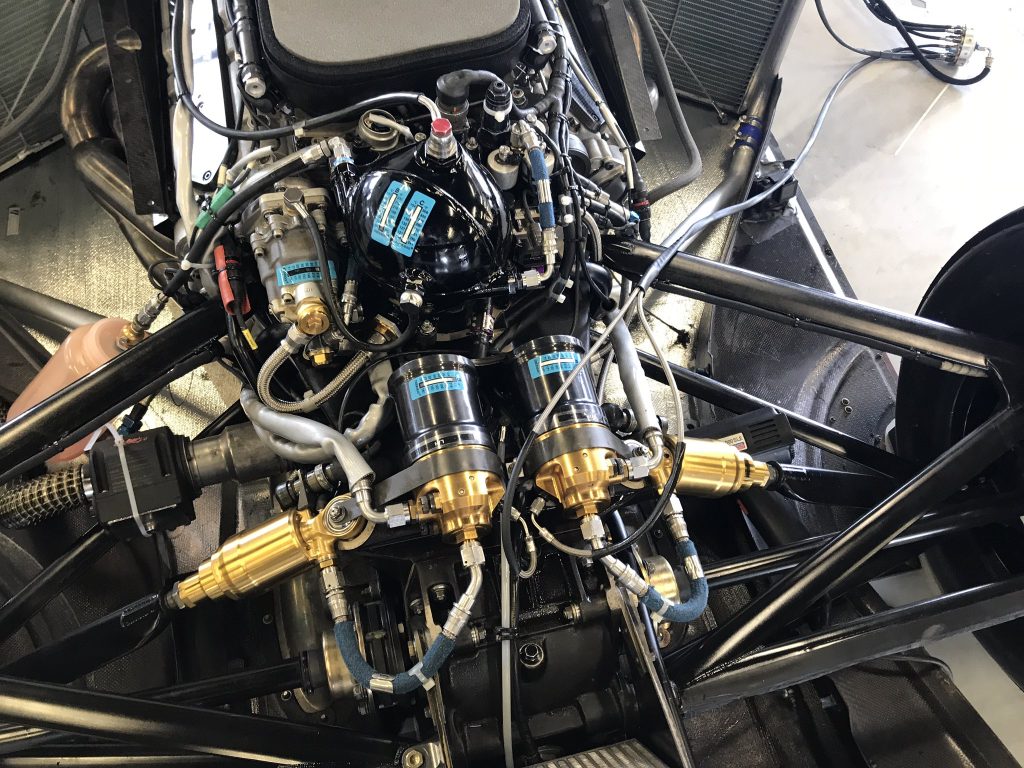

Check out this pile of madness:

That’s the Twitter account of Paddy Lowe, the former Williams tech chief. Let’s zoom in on his shot of the rear suspension:

. . . and this is the front, as shown earlier. The packaging is less dense, but it’s still a neat little alien-head tangle:

So much plumbing! One computer-controlled hydraulic system – one pump, many lines – for gearbox, downshift blips, suspension. Accumulators and lines and expansion tanks and hydraulic dampers, oh my!

They invented all of this for the purpose, my babies! They spun it up from scratch! It won all but nonstop! It stomped the field! A year later, in 1993, in the Williams FW15C, the idea stomped the field again!

Then, of course, it was banned. But you knew that.

Look at the front suspension again. The hoses are hydraulic lines. The gold cylinders atop each pushrod are the actuators; they translate hydraulic pressure into suspension motion.

The system still used mechanical springs. Their motion was controlled, and occasionally overridden, by the hydraulics. Because the rate of those springs was fixed, engineers labelled the system “semi-active.”

Each spring assembly was comprised of metal wave discs stacked in a canister-shaped housing. They were tied into the system hydraulically, fed load by sealed pistons. The front spring housings were mounted in the cockpit; the rears sat atop the gearbox in a similar arrangement. (Lotus experimented with a “full active” setup, no springs, the car supported solely by pressurised liquid. The failures were of execution, not concept, but spectacular anyway.)

The Williams suspension carried the same basic ideas front and rear. The system was elegant and efficient; more important, it worked. Nige did Nige things. The car went like blazes. That championship happened. Williams won the constructors’ title the same year.

For 1993, Mansell left F1 to drive Indy cars, where he immediately won a championship. Back in F1, the 14B’s replacement, the FW15C, carried on. It was an FW14B made faster and smarter and better, and it had antilock brakes. The car gave French driver Alain Prost the championship and Williams yet another constructor’s win.

F1’s sanctioning body, the FIA, banned active suspension and traction control for 1994. The move was part of a blanket outlawing of any tech seen as a “driver aid.” In the years since, the sport has fostered a different kind of innovation, far more subtle and harder to parse. The cars are more important than ever but less and less understandable to the layman with every passing year. More to the point, the obvious big leaps in tech are long gone. The dreaming is different.

***

That’s not how we want to end this, however, not on a sad note. So let’s pick a brighter one: the Easter eggs! When your car is a giant computer with magic suspension, you can do so much:

They could monitor and log tyre pressure without sensors! Early on, Williams engineers realised the data could spit neat information.

If you knew pushrod position at a given ride height, for example, and if you knew a tyre’s overall height at a given air pressure, you could work backward from pushrod position—which the car’s data would log—and calculate tyre pressure over the course of a lap.

They could programme switches to do nothing, simply to annoy the driver! Certain switches in the 14B’s cockpit could be mapped to change the car’s behaviour. Williams engineers would occasionally find a driver’s actions annoying, however, and map a switch to do nothing.

They would tell the driver the switch did… anything, really. A suspension change. A new shot of muffler-bearing lube. It didn’t matter. And the driver would believe them, because why would an F1 team lie to its driver? (They wouldn’t, of course. Unless that lie was a good joke that didn’t make the car slower.)

There was a push-to-pass feature! In racing, as in aircraft, aerodynamic design is always a tradeoff. Wings generate lift (or downforce, here) at the expense of drag. All else being equal, the laws of physics tell us that a wing of large lift will also give large drag.

This is part of why most race-car wings are adjustable. Change the angle at which an aerofoil faces the wind, you change the downforce and drag produced. Aero setup is thus always track-specific. At hyperfast circuits like Monza, where the long straights impact lap time more than the few corners, cars are usually trimmed for the lowest practical drag. Slower tracks see the opposite. It’s always a balance. In 1992, some smart cookie at Williams figured out how to give the 14B the best of both worlds. One of those cockpit buttons was programmed to instantly change the car’s front-rear angle into the wind. (This angle is called rake.) At the push of a button, the Williams could angle itself so steeply that its wings would stall, or stop producing downforce. In that moment, drag would plummet.

And so they told drivers to do that on the straights. Imagine the Drag Reduction System from modern Formula 1, just free to use whenever you like!

And now we’ve reached the natural conclusion of this missive. If you’ve made it this far, thank you for reading! Next time you find yourself in a dark pub full of cranky old men raising large pints to small TVs, yell a toast not to Max the Robot or poor, struggling Lewis, but to Our Nige! and recall fondly the magical mystery machine that was the Williams FW14B.

This story originally appeared on our US site. It has been edited slightly to remove some of Sam’s worst jokes. – Ed.